Arthur Ericson famously called concrete a ‘noble’ material. Nonsense. Concrete is a shape-shifter that will do whatever for whomever wherever. But that’s great, the fact it will assume whatever form you want. Every piece is a little different depending upon how much control you are able to exercise over the casting process and the solidity and subtle texture of smooth concrete underfoot and its ‘natural’ character is a welcome reprieve from our mass-produced, downward-leveling daily experience of life.

This was the second of three rooms we did for a professional couple living in a 1970’s split in Ahuntsic, and from our earliest discussions of the design of their new master bath they seemed prepared to go out on a limb a ways in the hope of achieving something a little out of the ordinary.

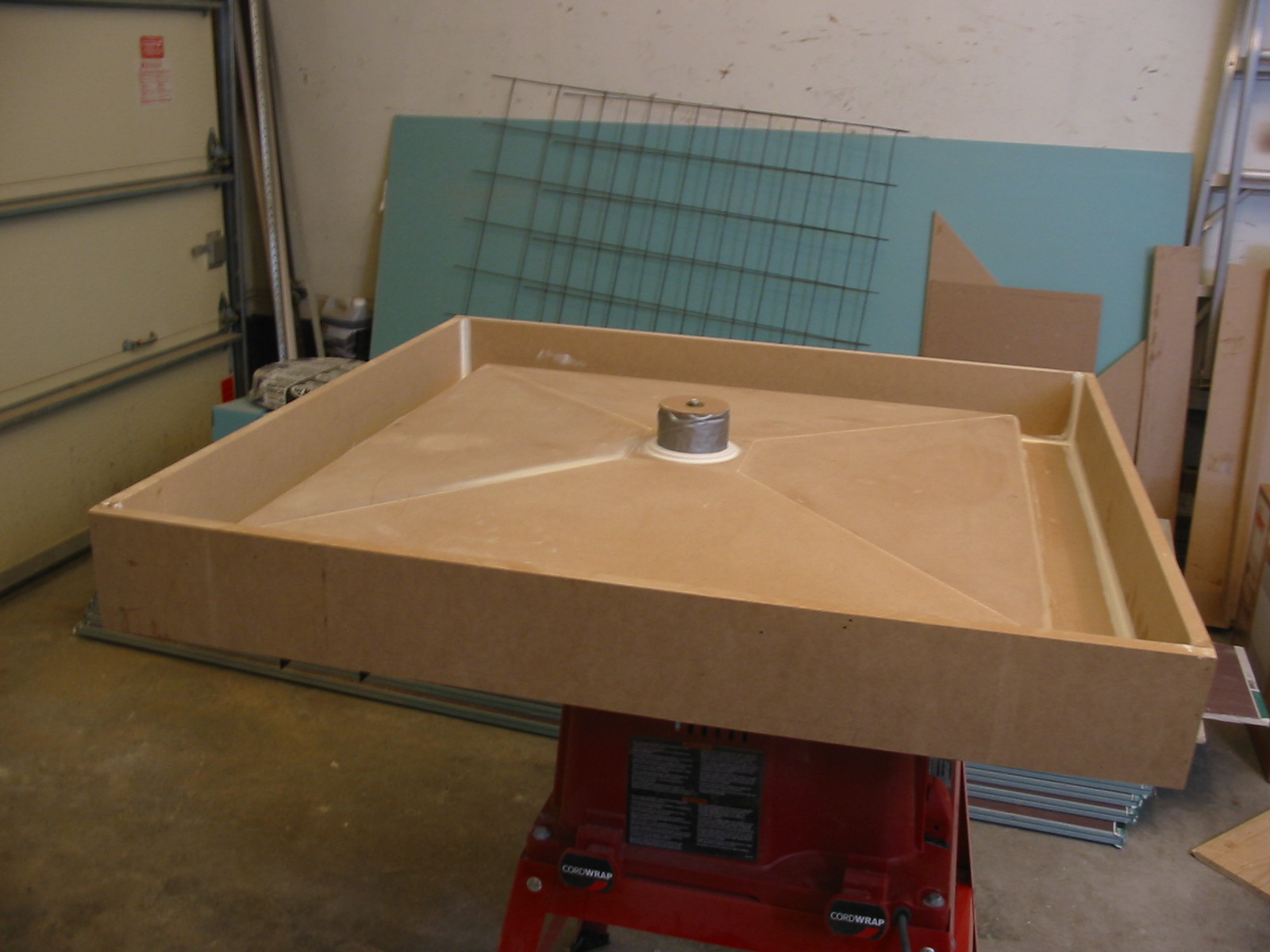

Casting a concrete shower base necessitates fabrication of a mould which is in the shape of the base in negative. The mould is the ‘female’ to the postive ‘male’ moulded part. If the base is not to be produced in any quantity the mould need not be an expensive affair.

The mould depicted was made in MDF and sealed with a fast-drying epoxy. What would otherwise have been sharp edges on the moulded part were chamfered by caulking the interior edges of the mould. Concrete expands as it cures and it is important to provide an adequate ‘draft’ or taper to the vertical sides of the mould to be able to ‘demould’ the part once the concrete has cured.

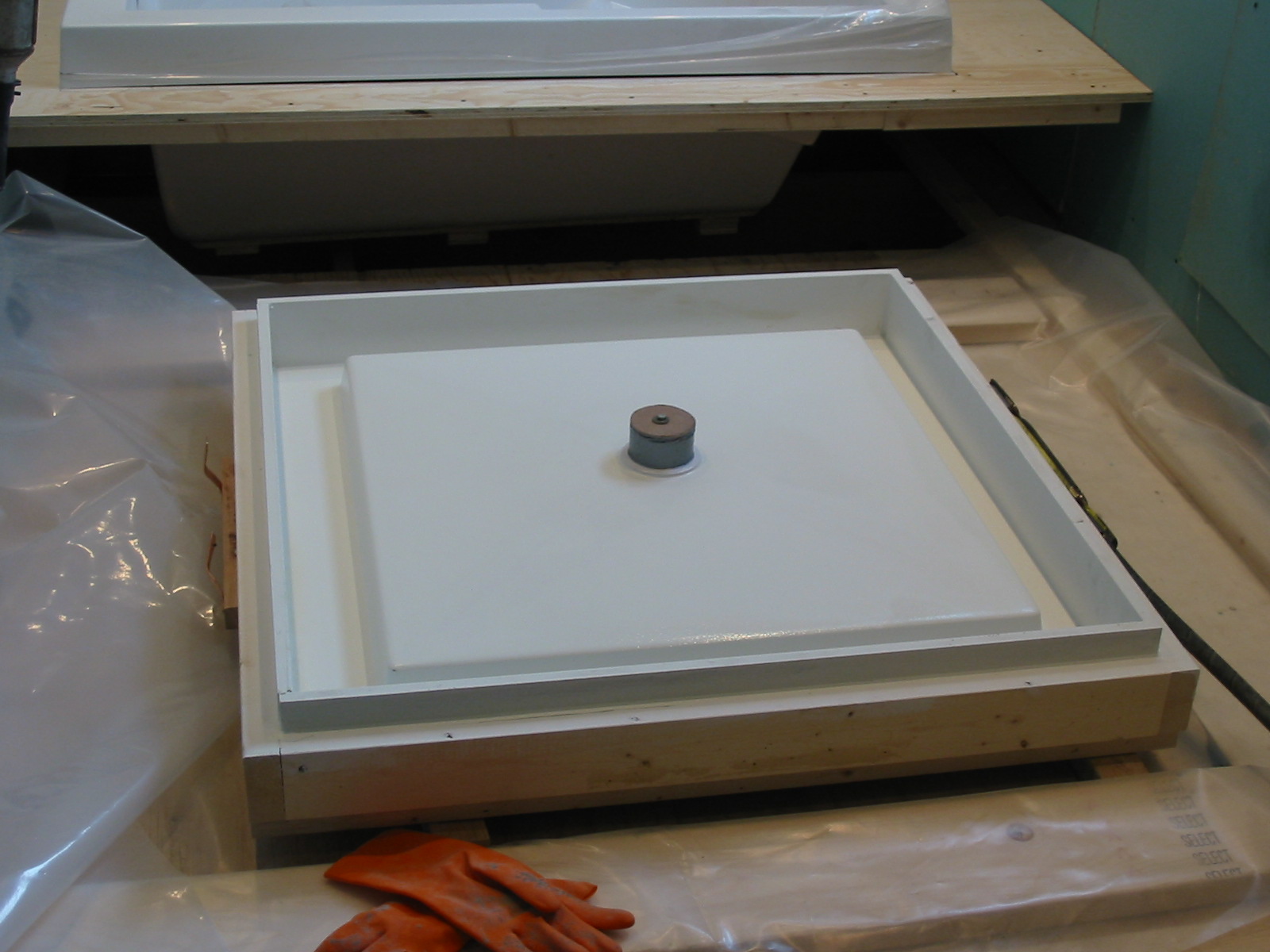

Although the painted interior of the mould (above left) is relatively smooth, it must nonetheless be waxed with what is referred to in industry parlance as ‘mould release’.

Concrete is strong in compression but weak in tension; its low tensile strength must be compensated for by the incorporation of steel reinforcing rod – ‘rebar’ – according to the stresses anticipated in the part (above right).

We fabricated the mould in our clients’ garage but poured the concrete adjacent to where the base was to be installed, uncertain as the whether either the stairs to the second floor, or our backs, would withstand the estimated 300-pound weight of the base.

It is very important that the mould be level prior to the pour; once the mould has been filled it must be vibrated to liberate any entrapped air. The vibrator is an eccentric rod inside a tube driven by powerful drill through a flexible extension. The mould was reinforced about its perimeter so as not to be destroyed by the violent shaking.

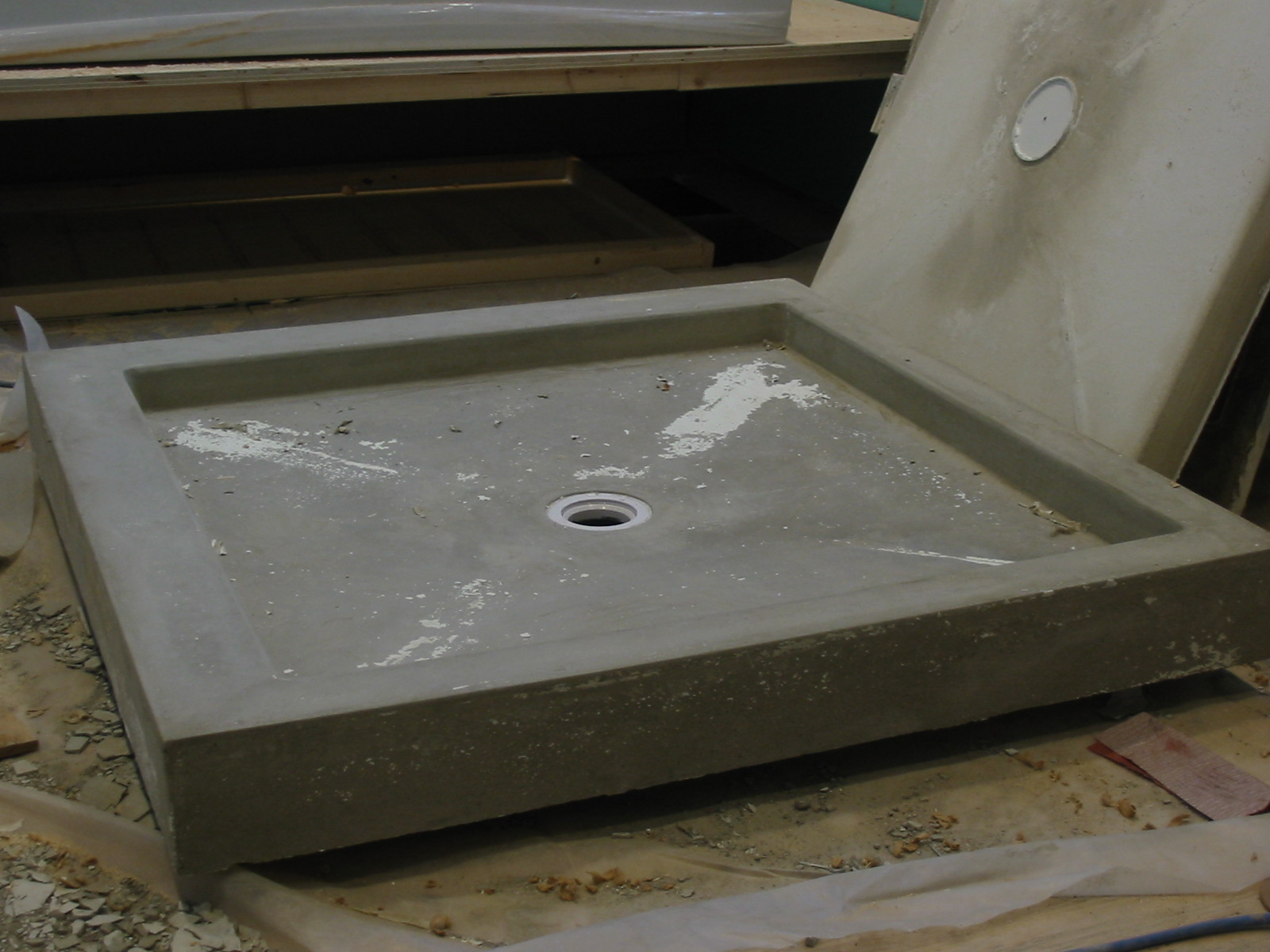

We did two pours, rejecting the first piece because of cavities due to entrapped air. The second piece had only minor imperfections of the kind that say the part was ‘hand-made’.

Site preparation implied opening the floor the width of the room and taking 2 to 3 inches off the top of the floor joists to bring the threshold surface of the base flush with the tiled floor; both joists were sistered on either side to provide better than equivalent resistance to bending.

The base was connected with the drain plumbing and lowered onto the joists according to plan using a block and tackle. The floor was replaced and minor surface deviations were corrected with mortar to ensure the finish surface of the floor would be flush with the base. The gap between the base and the adjacent floor tiles was filled with a flexible silicon caulk formulated for flexiblity and adhesion to mortar.

Man, great post. This is the kind of thing I understand. Thanks for setting it out there. Bethany Kale Massarelli